ISO 45001 "guidelines for occupational health and safety management system requirements and use guide" DIS2 draft was released in May 19th this year. Currently, ISO 45001 has now entered the final International Standard Version (FDIS) stage and is expected to be officially released in March 2018.

Development course of occupational health and safety management system

The management system of occupational health and safety rose in the late 1980s. At that time, a number of multinational companies and large modern combined enterprises, in order to strengthen their social concern and control the needs of the loss, began to establish a self-discipline management system of occupational health and environmental protection.

In 1996, the UK promulgated the guide for the management of occupational health and safety (BS8800); in the same year, the American Industrial Health Association (AIHA) formulated a guiding document for the "occupational health and safety management system"; in 1997, Australia and New Zealand put forward the principles, systems and support techniques of the occupational health and safety management system. In the same year, the Japanese industrial safety and Health Association (JISHA) proposed the guidelines for the occupational health and safety management system, and the Norway Classification Society (DNV) formulated the certification standard for the occupational health and safety management system.

In 1999, 13 organizations, such as the British Standard Association (BSI) and the Norway Classification Society (DNV), put forward the standard of occupational health and Safety Assessment Series (OHSAS), namely, OHSAS 18001 "occupational health and safety management system - standard" and OHSAS 18002 "occupational health and safety management system - OHSAS 18001 implementation guide". In 2007, OHSAS 18001 was further revised to further integrate its language and architecture with ISO 9001 and ISO 14001 standards.

Until 2013, the international organization for Standardization (ISO) began to develop a new standard - ISO 45001 "requirements and guidelines for the management of occupational health and safety", which was used to replace the OHSAS 18001 standard.

Why do you want to convert OHSAS 18001 into a ISO standard?

Global integration is more authoritative, easier to integrate and easier to manage.

First of all, according to the survey, about 45 countries currently use the OHSAS 18001 standard architecture to manage their occupational health (occupational health management, safety management, health management abbreviation) system. Although a wide range of applications, but not global, and converted to ISO standard, only its members have nearly 70 countries, so that its application scope is only one step. At the same time, ISO standard is a globally recognized standard, not only to further expand its scope of application, but also to make it more authoritative.

Secondly, ISO has international professional knowledge. Through ISO member organizations, there are nearly 70 participating countries or observers participating in the development of ISO 45001.

Third, many organizations are now using ISO management system standards, which will make it easier to integrate them with other occupational health and safety standards. At the same time, the committee is also more concerned about the possibility of integrating with ISO 14001 for many small businesses that may have only one person to manage security and environmental issues.

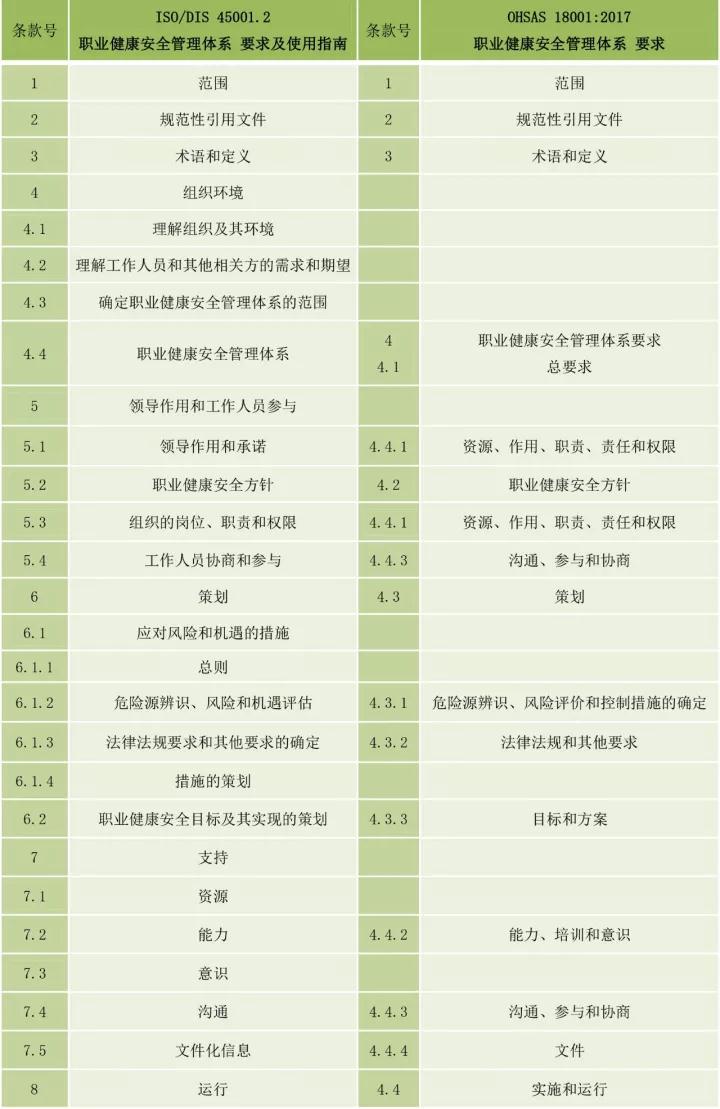

The difference between ISO 45001 and OHSAS 18001

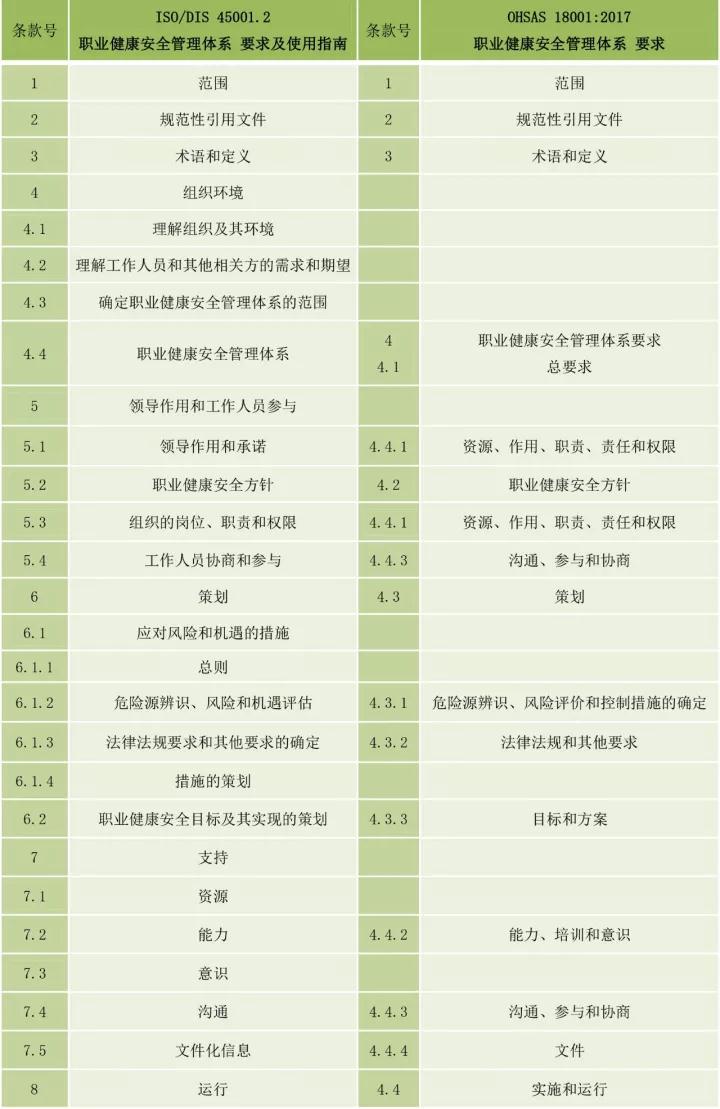

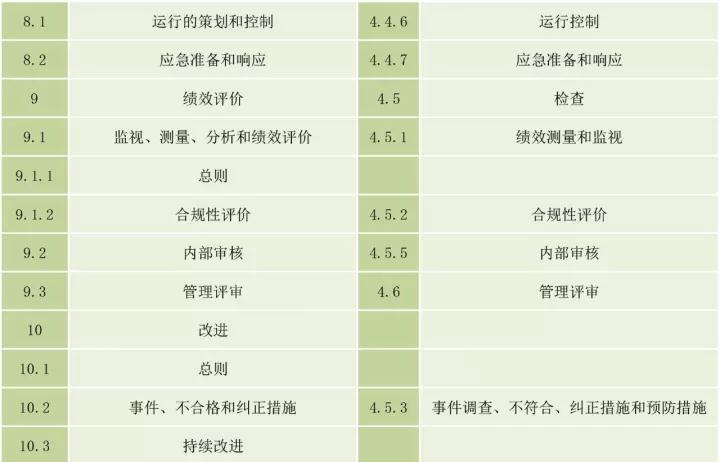

ISO 45001 is built on the existing OHSAS 18001 specifications, the main objectives are the same, are to improve the organization's occupational health and safety performance. At the same time, there are the following differences between the following 1 frameworks:

Using the advanced structure of the ISO management system

More attention to the "organizational environment"

Emphasizing the responsibilities and leadership of the top managers

More attention to management responsibilities

Stress based on risk - based thinking

More attention to monitoring and measurement of performance

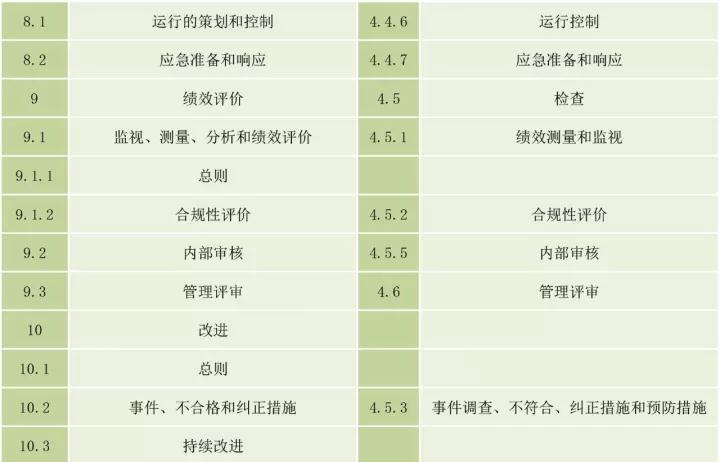

Table 1 the correspondence between ISO 45001.2 and OHSAS 18001:2007

In the new standards, an organization will focus not only on its immediate health and safety issues, but also on the larger social expectations. Organizations need to take into account their subcontractors and suppliers, as well as, for example, how their own work affects neighboring neighbors. This would be broader than simply focusing on the conditions of internal employees, meaning that organizations cannot simply "graft" their risks through outsourcing.

ISO 45001 stresses that these occupational health and safety factors are reflected in the organization's overall management system and require greater recognition from management and leadership. This will be a big change for those who are currently used to authorizing the responsibility to a security manager instead of being fully integrated into the organization. ISO 45001 requires occupational health and safety factors to be an integral part of the overall management system of the organization, not just an additional part.

Standards require organizations to identify risks and opportunities that organizations need to address when planning occupational health and safety systems. Risks and opportunities exist in the organization's risk sources, compliance, and the environment and stakeholders' needs and expectations. The standard requires organizations to take measures to deal with risks and opportunities to ensure that the system can achieve the expected results of the organization and achieve continuous improvement in the occupational health and safety of the organization.

Similarities and differences between SO 9001, ISO 14001 and ISO 45001

The biggest difference between ISO's three standards is its different objects:

The quality management system established by the organization according to ISO 9001 standard is targeted at customers.

The environmental management system established by the organization according to the ISO 14001 standard is targeted at the society and related parties.

The occupational safety and health management system established by the organization according to OHSAS 18001 standard is targeted at employees.

ISO implements the same points of three standards:

The general principles and objectives of organizing and implementing management are the same.

The three standard uses a common process pattern structure with similar structure for easy use.

The principle of the system is PDCA (plan execution check improvement) cycle.

There is a need for a cultural management system.

It is clear that the division of responsibilities should be documented.

They all proposed continuous improvement through system operation.

All have made commitments to comply with regulations and other requirements.

It is proposed that internal audit and management review be used to evaluate the effectiveness, suitability and conformity of the system.

All requests for management review and training education for nonconformities.

They all require the top management of the organization to appoint management representatives to establish, maintain and implement the management system.

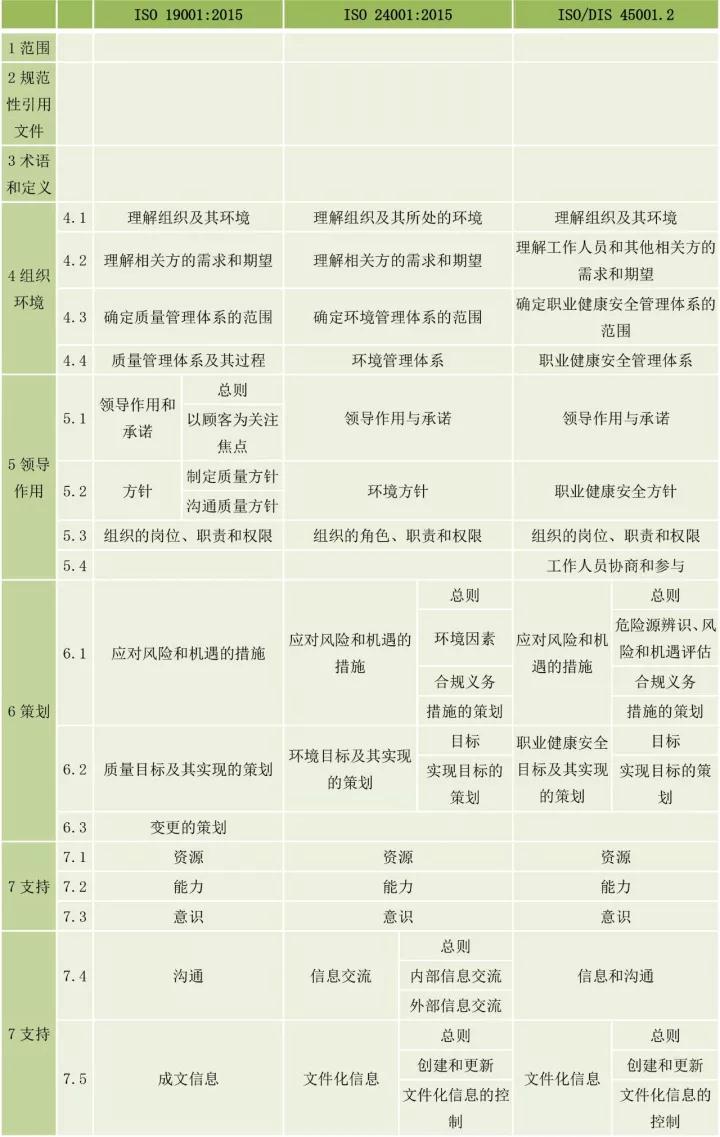

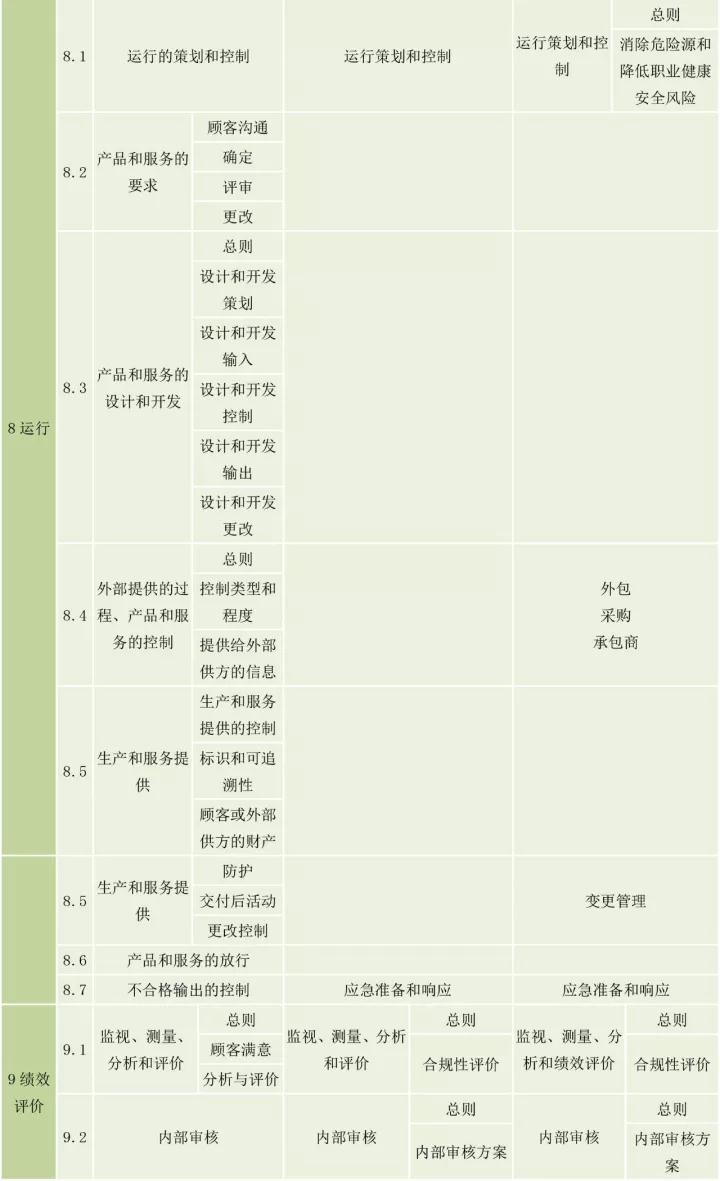

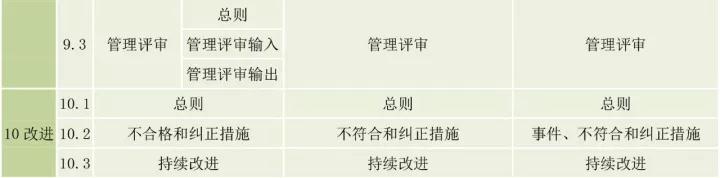

ISO 9001, ISO 14001, ISO 45001 framework integration

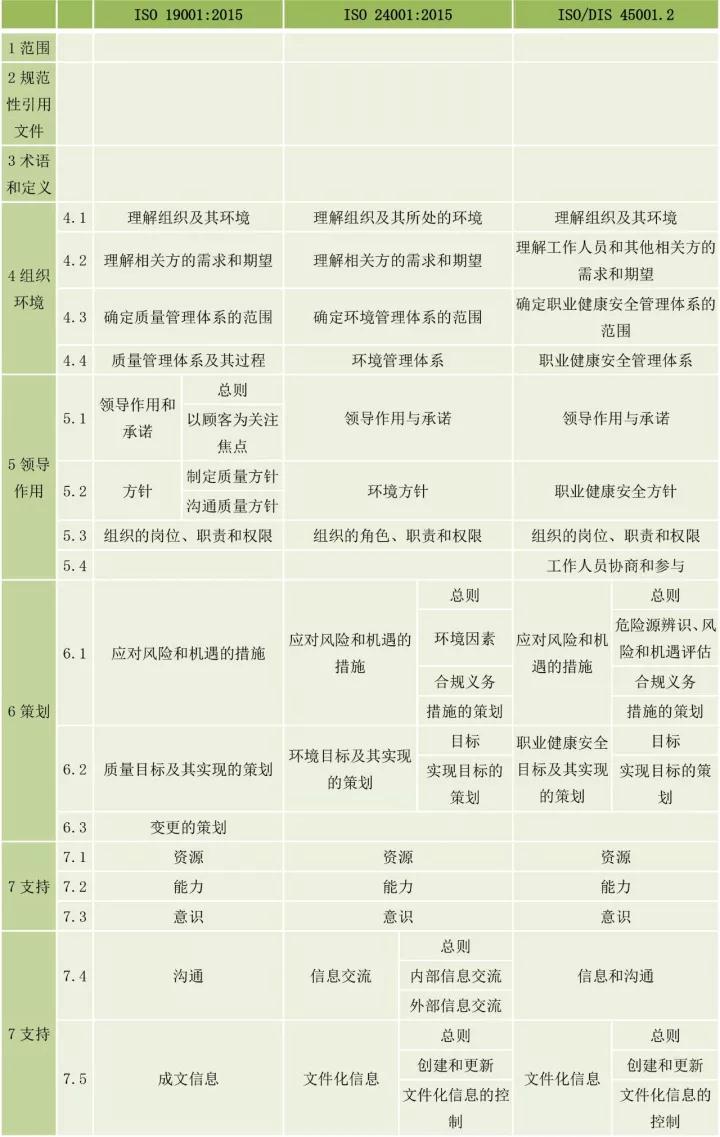

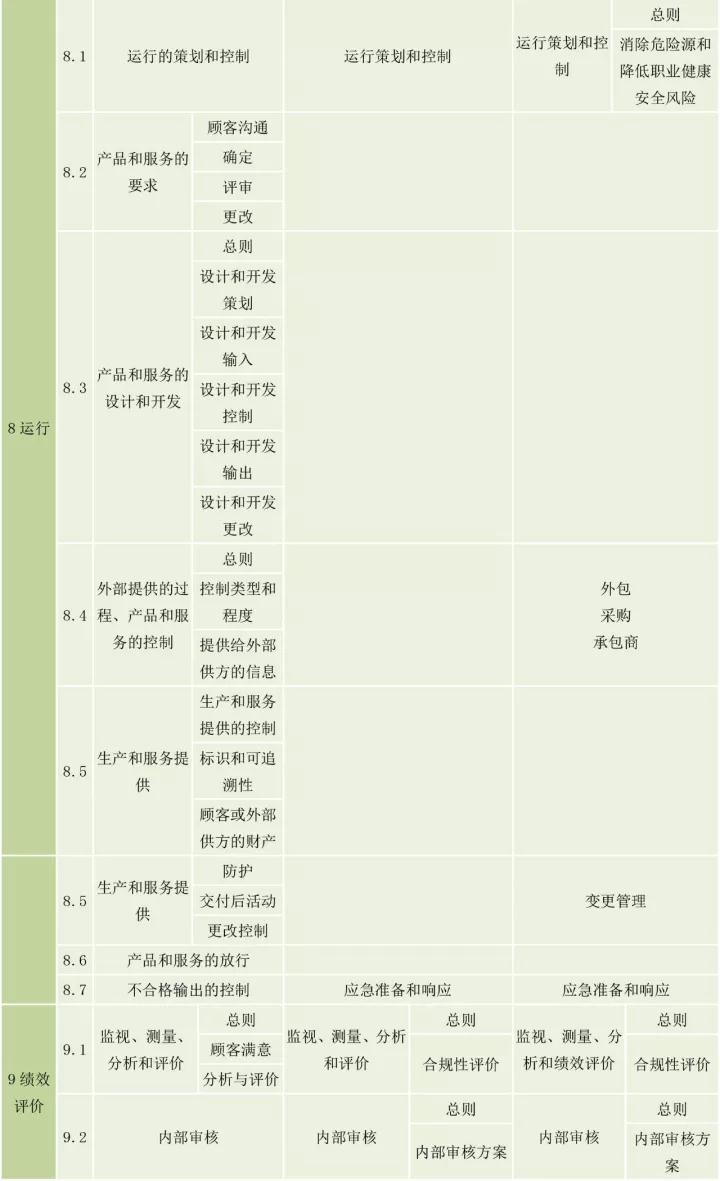

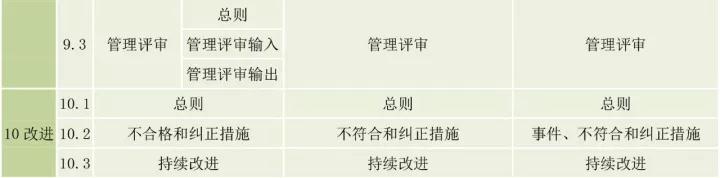

In China, the organization integrates the various management systems. The quality, environment, occupational health and safety management system is the ISO standard, and the high order structure is used, which provides convenience for the integration of the system. In Table 2, the framework of the three systems corresponds to the merger, which can be used for reference by readers.

Table 2 ISO 9001, ISO 14001, ISO 45001 framework integration

5 steps of organization to maintain health and safety

The organization can maintain its health and safety in the course of its work by following five steps.

The first step is to identify all processes and activities in the workplace.

The second step, with the help of staff, is to check whether there are major hazards that may cause injury in certain activities. For example, pay attention to some dangerous situations / processes, including high work, machinery, electrical equipment, chemicals, construction activities and farm work.

The third step reduces the risk of serious injury (accident or long-term pain), which can be done by eliminating the risk sources, changing the workflow, and protecting the staff and so on. For example: long term exposure to heavy objects, radiation, noise, vibration, visual display screen, chemicals, etc.

The fourth step is to verify whether the measures taken by the protection staff are in normal operation and whether they are complied with.

The fifth step is to look for ways to do better and safer.